Non-metallic materials such as leather, PU, fabric, paper, plastic, rubber, etc.

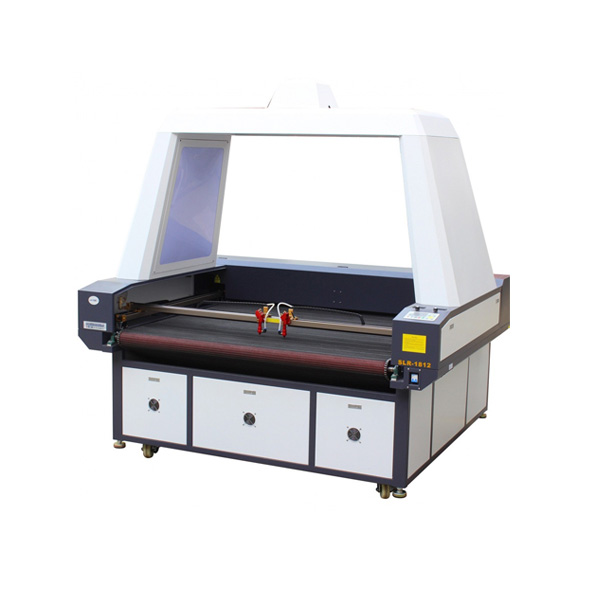

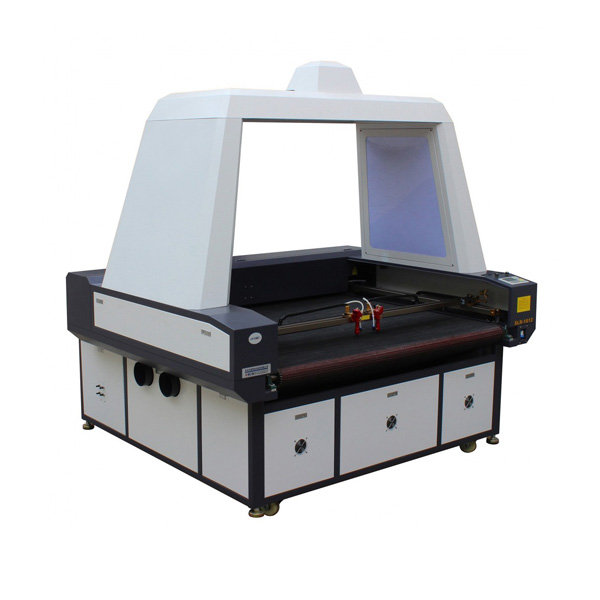

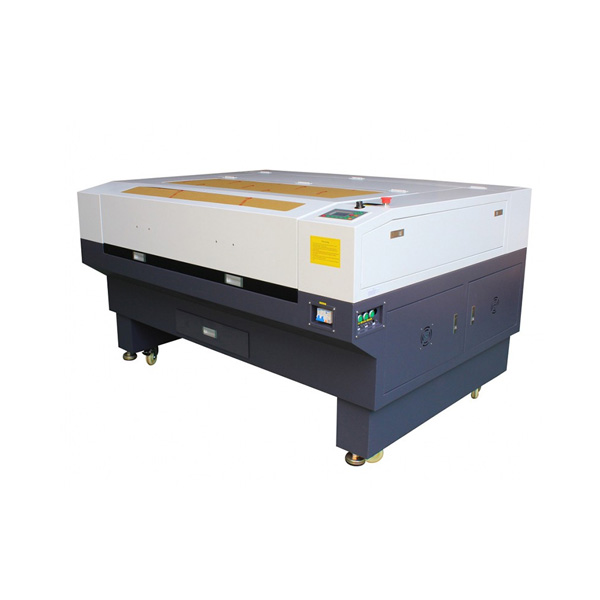

Sublimation Camera CO2 Laser Cutter

Buying A Competent Sublimation Laser Cutter From Us!

If you are looking for a globally recognized China sublimation laser cutter supplier, Dongguan Hunst Laser Technology Co. Ltd has to be the ultimate choice. Not only do we offer premium quality laser equipment to our prestigious clients, but we also satisfy all of their specific demands and requirements. We get buyers belonging to different regions of the world every day looking to invest in a highly precise and efficient laser machine. Our China sublimation laser cutter is exactly what you need to carry out a variety of tasks involving cutting activities. We aim to establish our company as a worldwide phenomenon by appealing to not one but multiple industries. These include the textile, bags, and shoe industry, etc.

Description

What Sets Our China Sublimation Laser Cutter Apart?

As a renowned China sublimation laser cutter supplier, we manufacture and provide equipment with the latest features and incredible parts. We wish to offer our clients an increasingly durable option to install in their factories in return for a very little amount of money. Let's take a look at the features of our products to help make up your mind: 1: It can locate the object in question using an automated SLR camera. 2: It works with greater efficiency and promotes high-speed processing without any downtime. 3: It comes with automatic feeding and cutting feature. 4: Our sublimation laser cutter has a huge format cutter capable of producing accurate results. 5: The stability and high performance of the machinery come from the stepper motors installed during the assembly procedures. An impressive characteristic is the presence of a wrinkle removal device to eliminate any deformation within the fabric and other processing materials. Making a deal with Dongguan Hunst Laser Technology Co. Ltd means securing your investment for years to come without requiring any significant replacements.

Do We Offer Additional Services?

Dongguan Hunst Laser Technology Co. Ltd understands clients' importance. We provide several after-sales services without charging much of your hard-earned money. Our equipment has a year-long warranty. Moreover, we also give free maintenance services for as long as the machine is functioning. You can personalize your equipment to suit unique needs as well.

1. It uses SLR camera to automatically locate the workpiece by comparing the camera graphic to the imported blueprint, avoiding the deviation of manual locating.

2. It is a large format cutter which can match and cut the graphic not large than 1.8m at one time, which greatly improve the locating and cutting efficiency.

3. Equipped with wrinkle removal device, which greatly reduce the deformation of the fabric, and it can automatically compensate to pinpoint deformation of the fabric which ensures the accuracy of cutting.

4. Supporting automatically material feeding and cutting, supporting high-speed continuous curve cutting, so it works in a very high efficiency.

5. Automatically tracing the edges after shooting, no premade template is needed, so it is very conveniently.

6. It uses high performance stepper motors or servo motors to ensure stable, precise and quick working.

EMAIL US

EMAIL US