CO2 Laser Cutter Especially for Textiles

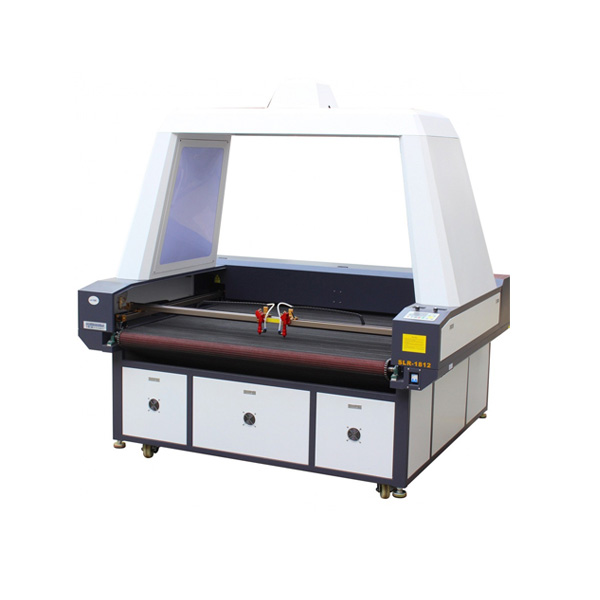

HUNST LASER designed this machine with the partners in India and Sri Lanka to satisfy the cutting demanding of lace cloth. It supports garment CAD technology to conform to the trend of the times in textile industry and is gradually used by large enterprise and achieved good results.

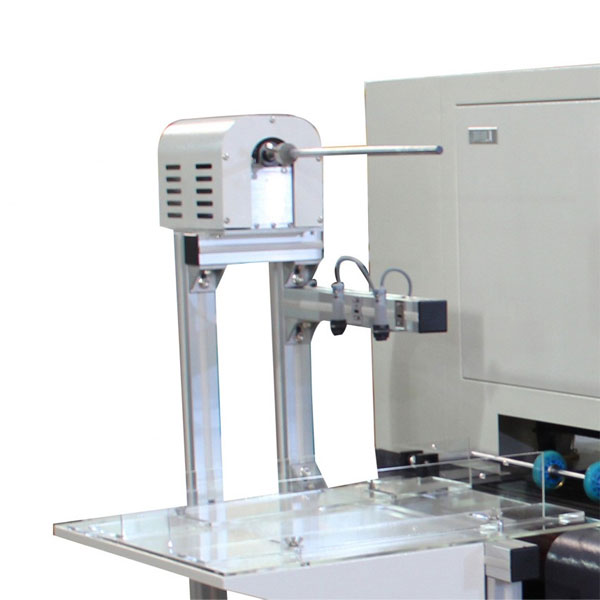

This machine is equipped with automatically material feeding system and camera. It can automatically recognize patterns of the lace and then cut out the shapes on the materials. It is efficient, labor-saving and could help you to create competitive advantage in textile industry.

This machine is equipped with automatically material feeding system and camera. It can automatically recognize patterns of the lace and then cut out the shapes on the materials. It is efficient, labor-saving and could help you to create competitive advantage in textile industry.

Description

Video:

Features:

1. Automatic tension feeding. The lace cloth is tiled on the conveyor working table on one side of the machine, when the current lace cloth have been processed, the next one will be automatically feeding by tension feeder without distortion and deformation.

2. Smart layout and cutting. This machine can smartly layout the material according to the design, which can save 20% materials than traditional punching and shearing, and the cutting is performed with high precision along the edge ensures high product quality.

3. Intelligent integrated control. It is controlled by computer and provides easily one-click operation. So it is highly automated and labor-saving.

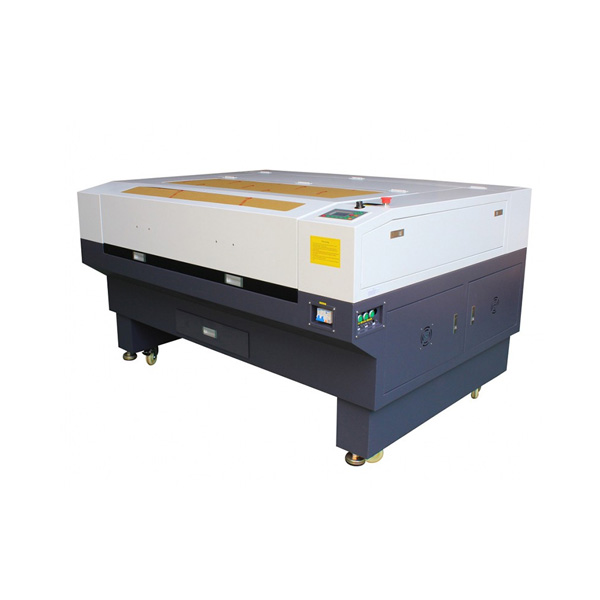

Technical Parameters

| Model | ETS-4012LF | ||

| Effective working travel | 400*1200mm | ||

| Laser power | 100w/130w/150w; | ||

| Cooling type | Water cooling system | ||

| Feeding method | Auto feeding system | ||

| Industrial CCD camera | 18 million pixels | ||

| Maximum cutting speed | 0~36000mm/min; | ||

| Repeat position accuracy | ±0.2mm | ||

| Operating voltage | 220V±10%; 10A; | ||

| Dimension | 2580*1178*1950mm | ||

| Net weight | 950KG |

Application

GET IN TOUCH

Other Products

EMAIL US

EMAIL US