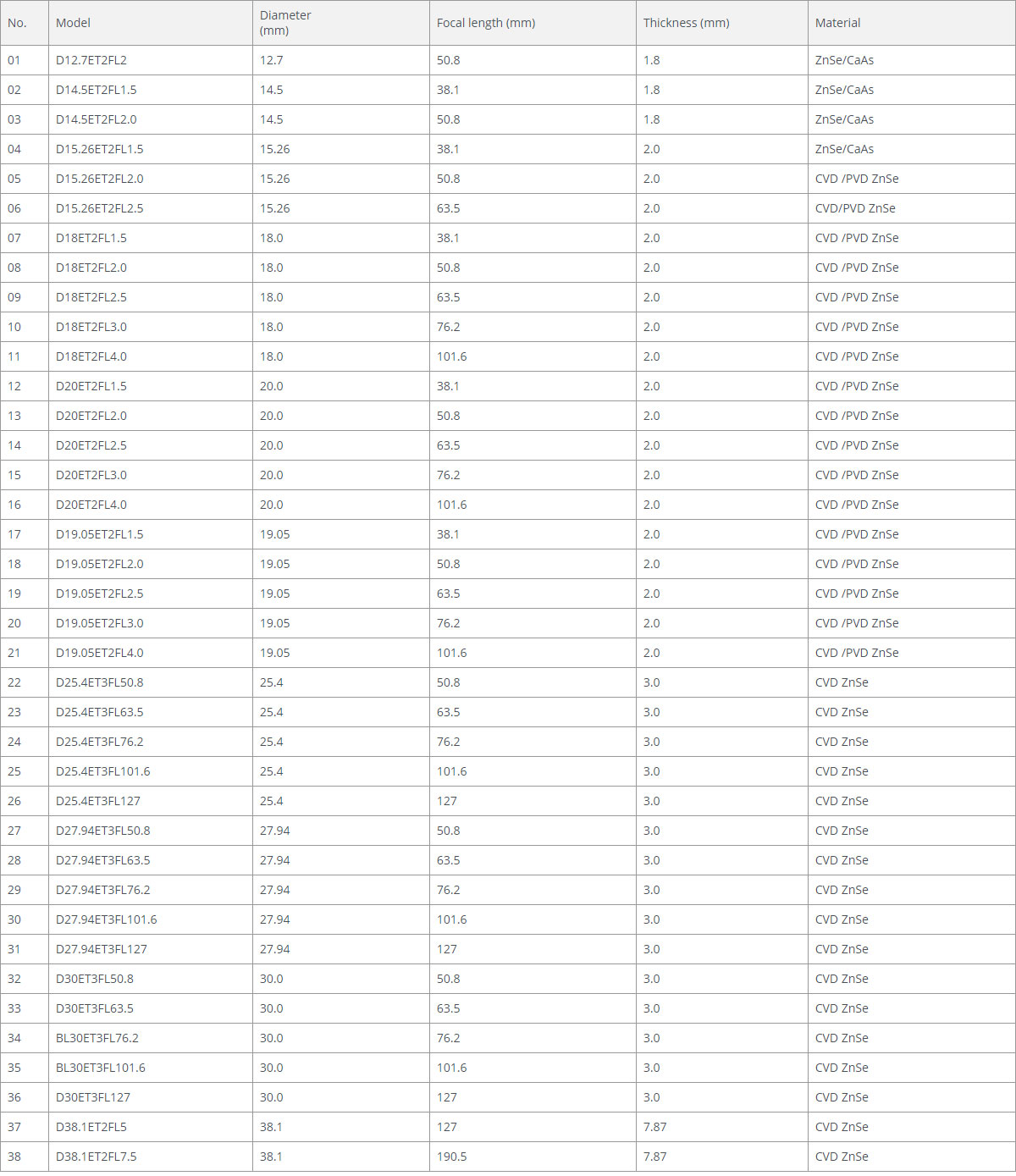

All the CVD ZnSe focus lenses with common diameters like 18mm, 19.05mm, 20mm, and 25mm are available in Eastern Laser, and we also provide trailer-made laser focus lenses with various diameters to satisfy any requirement.

Laser Focus Lens

Description

FL: focus lens with single focus

10.6: 10.6um in wavelength

F:Focal length (mm)

D: Diameter (mm)

T:Thickness(mm)

yy: other applications

1. When using optical elements, you should always wear powder-free finger cots or rubber / latex gloves in that dirt and oil stains will seriously contaminate optical elements, resulting in a significant decline in performance.

2. Do not use any tool to manipulate optical elements, including tweezers.

3. For the purpose of protection, optical elements should always be placed on provided lens paper.

4. Do not place optical elements on hard or rough surfaces because infrared optical elements can be easily scratched.

5. Do not clean or touch the surface of exposed gold or copper.

6. All materials used to produce infrared optical elements are fragile, whether they are single crystal or polycrystalline, whether the grains are large or small. The materials are not as strong as glass, and they can not bear the same procedures as those of glass optical elements

7. Because when you clean optical elements installed on frames, a variety of problems may occur, it is recommended that you only resort to the cleaning proced

EMAIL US

EMAIL US